Robust Perching via Touch: Embodying Tactile Grasping on Aerial Robots

TL;DR: We equip a flying gripper with binary touch sensors on its phalanges. Based on the tactile cues it can fine tune its position and orientation to align with perching targets ensuring a safe grasp, without the need for precise target knowledge.

Overview

Methods & System

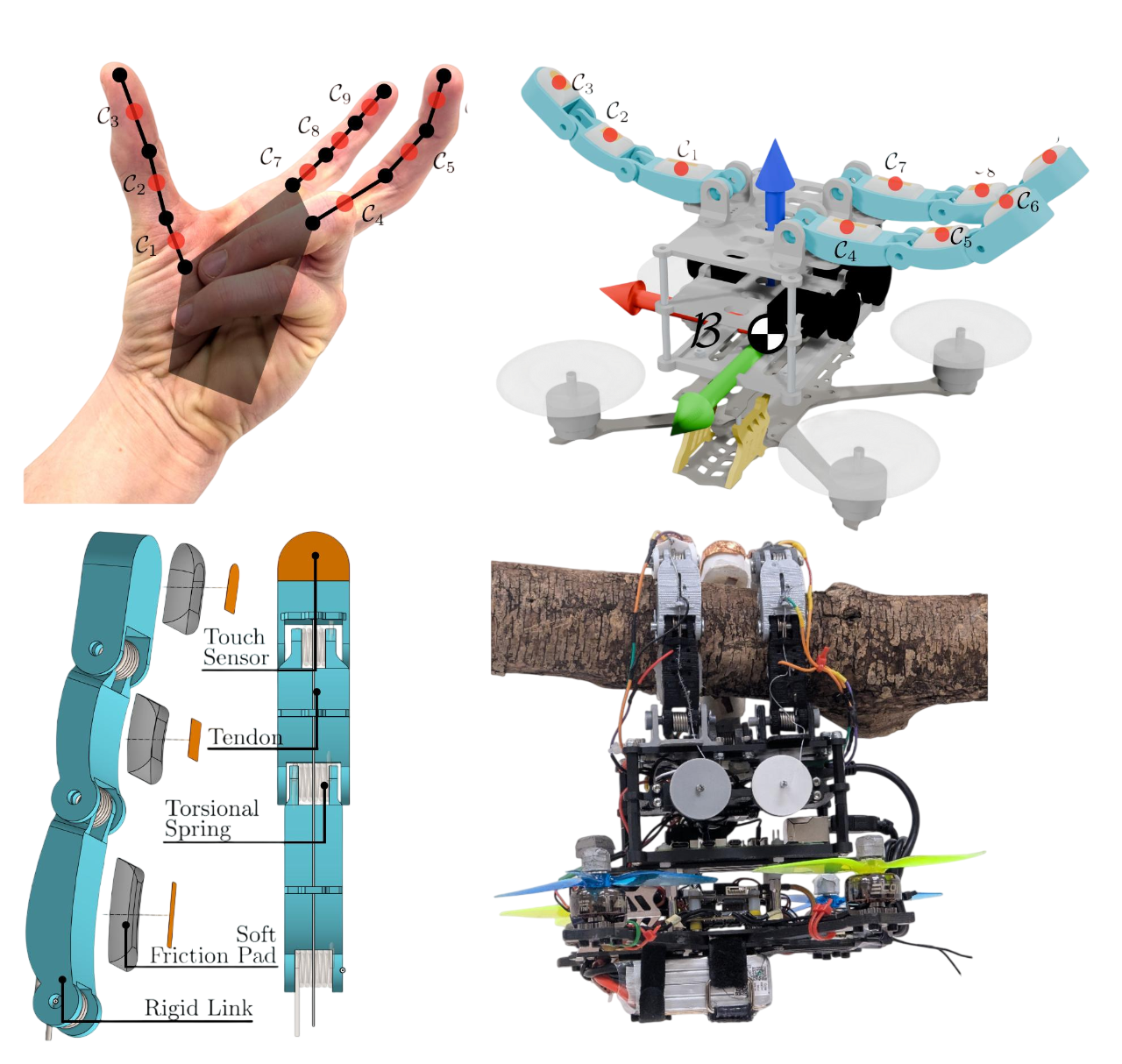

The system consists of a quadrotor with a three-fingered anthropomorphic hand mounted on top. Inspired by the human hand, the gripper is mechanically compliant to passively conform to various shapes. Each finger has torsional springs for passive closing, tendon actuation for opening, and capacitive touch sensors on each phalange. These binary signals provide feedback on contact events.

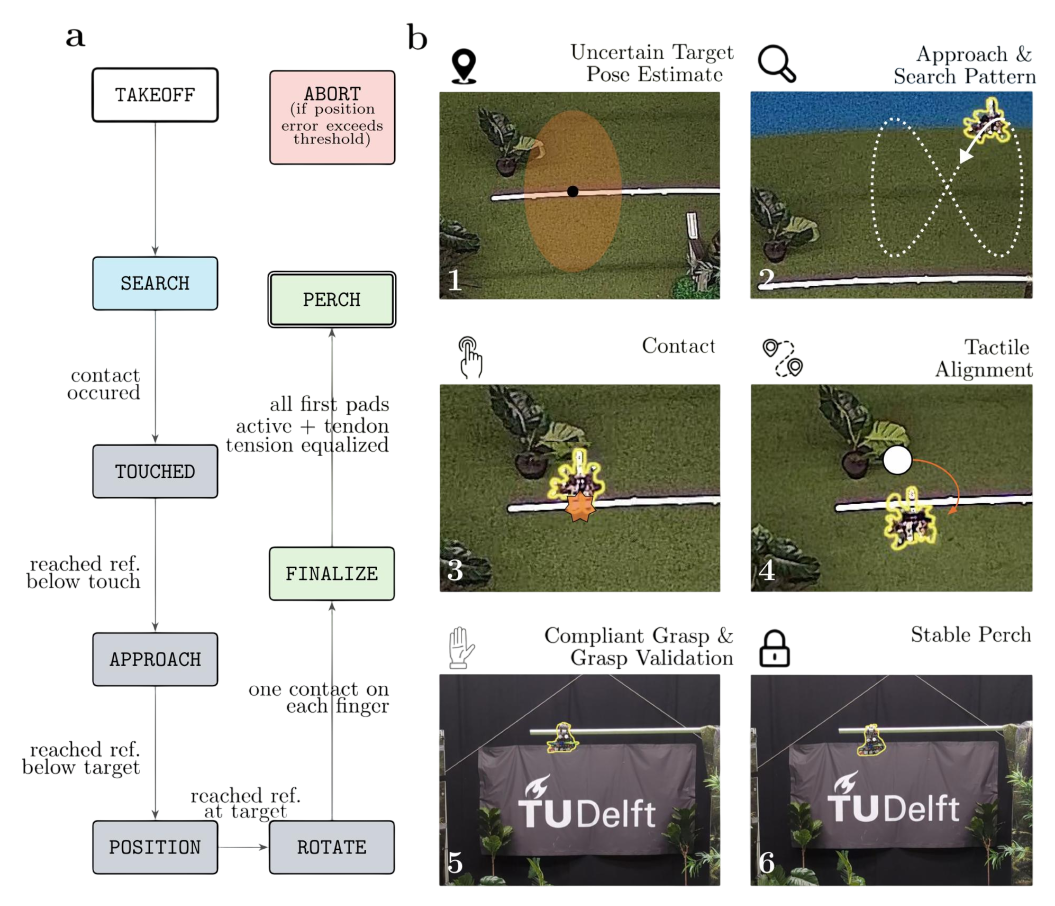

A finite state machine (FSM) governs the perching process: from takeoff and a figure-eight search pattern, through initial contact, approach, orientation alignment using tactile cues, grasp finalization, and passive perching. An abort state ensures safety if errors exceed a threshold.

Finite state machine governing the tactile perching maneuver.

Hardware Prototype

Interactive 3D model of the tactile gripper mounted on the quadrotor. You can rotate and zoom to explore the design. The tactile gripper mounted on a quadrotor. Torsional springs ensure passive closing, tendons actuate opening, and copper-foil capacitive sensors detect contact.

Mechanical Design:

The gripper has three rounded finger segments connected by spring-loaded joints that naturally keep the fingers closed. Soft silicone interiors improve grip and compliance, with contact sensor interfaces mounted on top. A tendon system driven by spools allows each finger to open when actuated, while releasing the tendon makes the finger close again. All design files are available on the project page.

Electronics & Control

The gripper is mounted on a SpeedyBee FS225 V2 drone frame powered by a 4S battery. A Pixracer R15 running PX4 handles flight control, while a Raspberry Pi 5 coordinates with a Teensy 4.0 to actuate the finger tendons using three servos. The Raspberry Pi also processes input from the touch sensors.

Contact Sensing

Each finger is equipped with capacitive touch sensors made from copper foil and an MPR121 controller. When the fingers touch a conductive surface, the change in capacitance is detected and converted into binary contact signals for reliable touch feedback.

Experiments

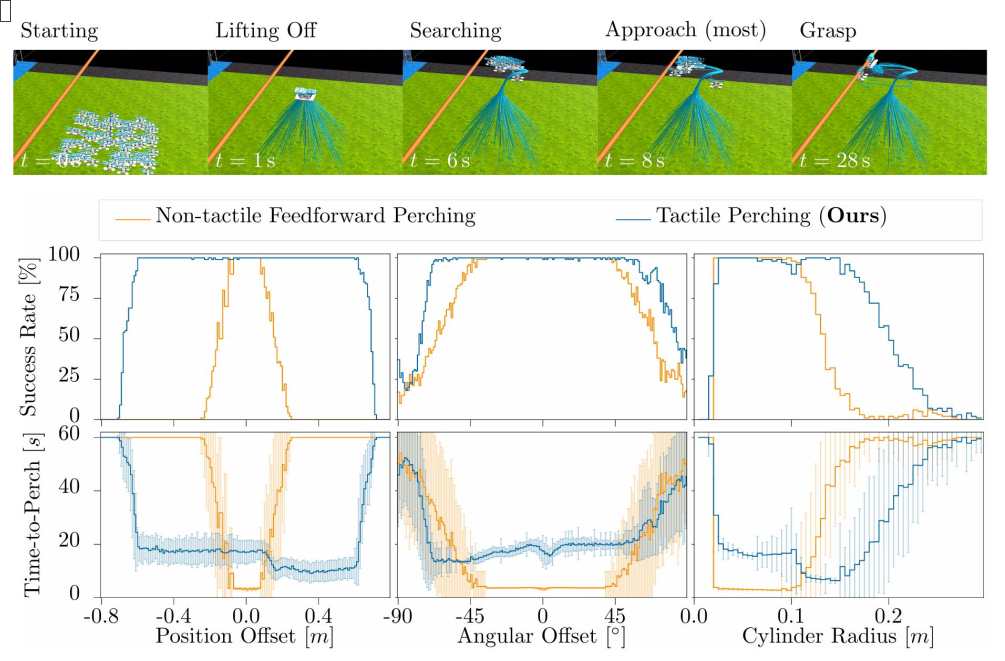

We validate our approach in simulation and real-world experiments. In Monte-Carlo simulations, the tactile-based method achieved over 95% success rate with positional offsets up to 0.6 m and orientation offsets up to 50°. Compared to a feed-forward baseline, tactile perching is far more robust to uncertainty.

Simulation results comparing feed-forward perching (orange) and tactile perching (blue).

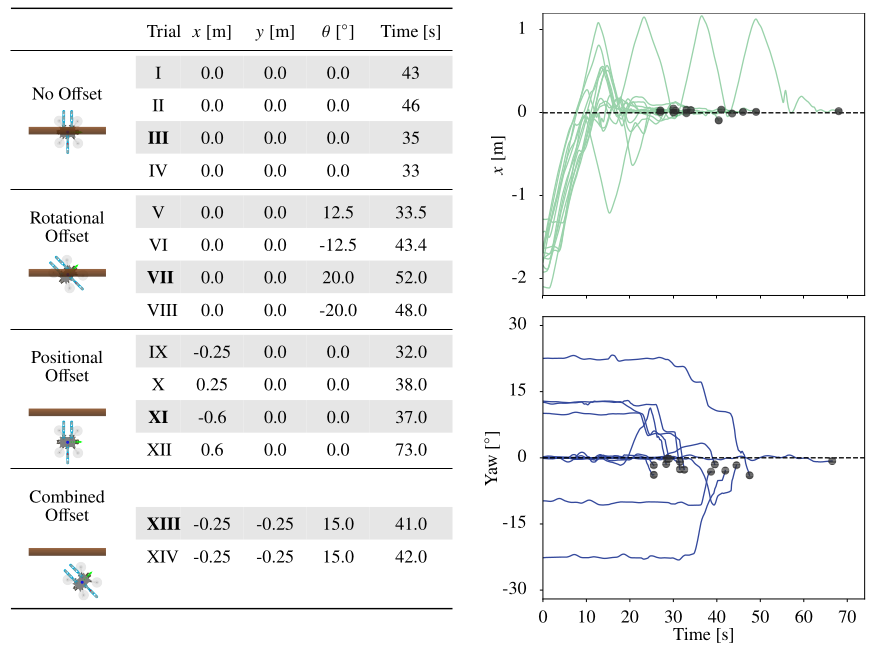

In hardware experiments with our prototype, the drone successfully perched in 14/14 trials across different positional and rotational offsets. Thanks to the gripper's compliance, it adapted to a wide range of targets such as branches, beams, and even irregular objects like a traffic cone.

Example trajectories from real-world flight trials with different initial offsets. All trials converge successfully to the target pose in a stable perch indicated by the gray circles.

Conclusion

By integrating tactile sensing into a compliant gripper, we enable aerial robots to perch reliably in uncertain, cluttered environments. Unlike prior methods, this approach does not require precise target knowledge and is robust to occlusions. Results in both simulation and hardware show high success rates across a range of offsets and target types. Future work will explore richer tactile sensing and onboard state estimation for outdoor operation.

BibTex

The website template was adapted from John Barron and Michaël Gharbi.